Kanban explained

The first Kanban system was developed in the early 1940s by Taiichi Ochno for Toyota automotive in Japan. The word 'kanban' means 'visual sign' or 'card'. Kanban was also referred to as just-in-time manufacturing and was introduced to increase productivity while reducing cost-intensive inventory. The system helped to avoid supply disruption and overstocking of goods at different stages of the manufacturing process creating more value for the customer without generating more costs.

The Kanban concept was later successfully introduced to other sectors with the purpose to change the ways in which products and services were delivered.

Kanban is a change management system when the existing process is improved in small rather than large steps, leading to low or no resistance in the team and the stakeholders involved. To visualize the workflow, there is a Kanban board (a simple whiteboard) and sticky notes or cards. Each card on the board represents a task. This visualization provides transparency about:

- the distribution of the work

- existing bottlenecks

Once the Kanban board is filled with cards, you can see that some columns will get overcrowded with tasks. This will help you spotlight bottlenecks in your workflow and address them properly.

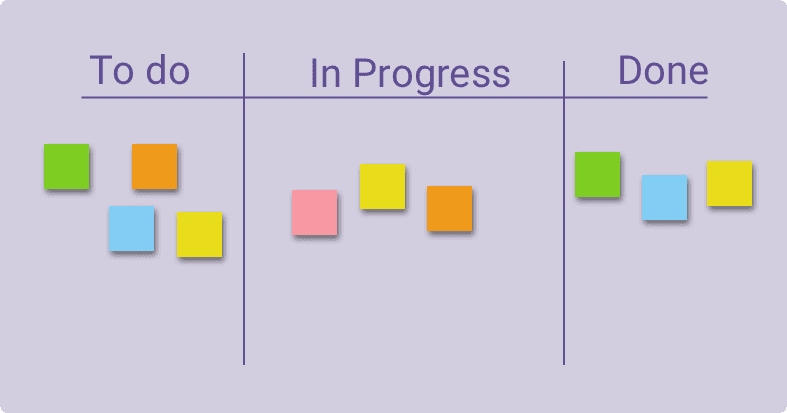

The simplest and the most classic Kanban board has three columns – 'To Do', 'In Progress' and 'Done'. Any company can benefit from applying the principles of the Kanban Methodology because when applied, it shows bottlenecks within the system and anything that might get in the way of smooth working practices.

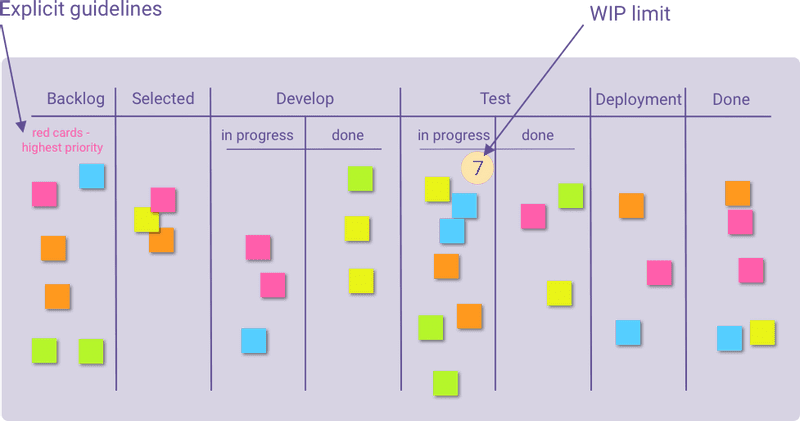

Kanban boards can be very elaborate depending on the complexity of the workflow. The boards may vary considerably from company to company and from project to project. Here is another example of the Kanban board, which has more than three basic columns:

However, in today's world of highly developed technologies, the Kanban board is not necessarily the actual board on the wall. There are many digital Kanban board solutions that have been developed to modernize the work and overcome the problems arising in remote teams.

The concept of 'Flow' is essential in Kanban. This means that the cards should flow through the system as smoothly as possible. Long waiting times or blockages signify that something should be changed in the workflow and everything that hinders the flow should be looked into.

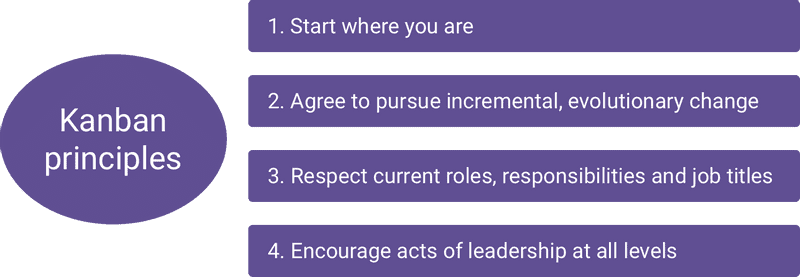

The 4 basic principles of Kanban

The Kanban method gradually improves organization's processes. To increase the benefits to your business process, 4 basic principles of Kanban should be followed.

Start where you are

The Kanban method is less prescriptive and less disruptive to begin implementing as it is the original 'start where you are' method. Kanban methodology should be applied directly to the current workflow since it's very flexible. Any necessary changes can be applied gradually at a pace the team is comfortable with.

Agree to pursue incremental, evolutionary change

Sweeping changes usually encounter resistance due to fear or uncertainty, therefore, they are discouraged. Kanban encourages to make small incremental changes rather than making radical changes that might lead to resistance within the team and organization.

Respect current roles, responsibilities and job titles

This principle helps the organizations overcome the typical emotional resistance and the fear of change. Kanban recognizes that existing roles, responsibilities and job titles have value and are worth preserving. The Kanban method does not encourage changes as long as existing roles and functions are performing well.

Encourage acts of leadership at all levels

Kanban encourages continuous improvement at all levels of the organization and new ideas may come from any member of the team, regardless of the position or status.

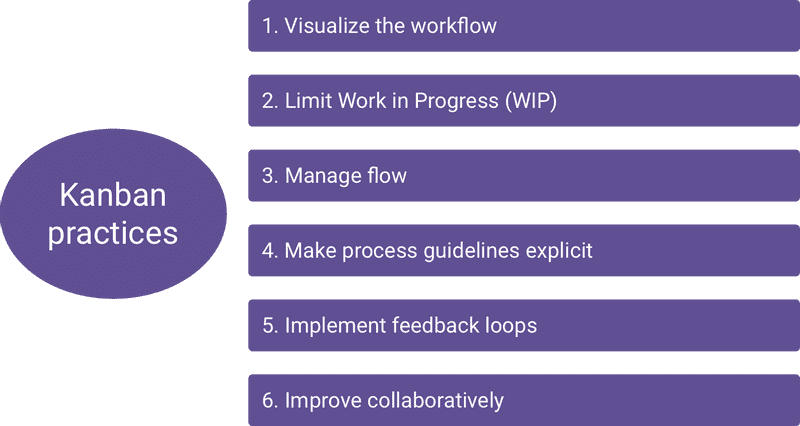

The 6 basic practices of Kanban

There are six basic practices that need to be present for the successful implementation of the Kanban Method.

Visualize the Workflow

You need to visualize, whether on a physical board or an electronic Kanban Board. To visualize your process with a Kanban system, you will need a board with cards and columns, where each column represents a step in your workflow and each Kanban card represents a work item. Different colors of stickies or cards may signify either different types of service or work. The progress can be easily tracked as the cards are moved from 'To do' column to 'Done' column.

Limit Work in Progress (WIP)

Limiting work-in-progress (also referred to as a 'Pull-system') is fundamental while implementing the Kanban Method. By limiting WIP, you minimize multitasking and encourage your team to complete work at hand first before taking up new tasks. Setting maximum items per stage (column) ensures that a card is only 'pulled' into the next step when there is available capacity. However, it may not be easy to decide what your WIP limits should be initially. In Kanban method, it's more important to complete work than it is to start a new one. Therefore, the teams should adhere to WIP limits and get each piece of work through the system to 'done' column.

Manage Flow

The whole idea of implementing a Kanban system is to create a smooth healthy flow of work items through the production process. Depending on how well the workflow is defined, the team will observe either a smooth flow within WIP limits or work piling up in one column. Kanban helps your team analyze the system and make adjustments to improve the workflow.

Make Process Policies Explicit

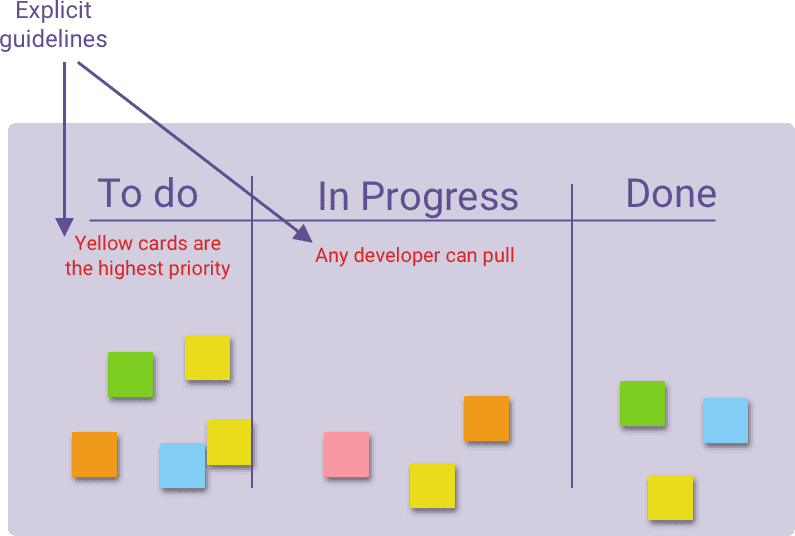

The team would not take part in something they do not believe is useful. By formulating explicit process guidelines, you create a common basis for all team members to understand how to do any type of work. The policies can be at the board level, at a swim lane level or for each column. The policies must be defined explicitly and visualized usually on the top of the board and on each lane and column. Here is a simple example of the board where the guidelines are explicitly defined.

Feedback Loops

Feedback loops are necessary for knowledge transfer. They lead to delivering the right work, the right product to the customer in the shortest possible time.

Improve Collaboratively

Continuous improvement and sustainable change within an organization can be achieved through a shared image of possible improvements and a collective understanding of the problems that need to be dealt with. The Kanban Method is an evolutionary improvement process. It helps you adopt small changes and improve gradually at a pace and size that your team can handle easily.

Kanban can't solve all of the problems, but it makes the lives of project managers easier. There are many benefits to use the Kanban Method but I will limit them to the most significant ones:

- Flexibility - teams are usually not bound by timeboxes

- Increased productivity and quality - Limiting WIP helps increase productivity and quality

- Focus on continuous delivery - teams are focused on flowing work through the system to completion and not starting new work until work in progress is completed

- Reduction of waste - transparency makes waste visible and easy to remove

- Collaboration – Kanban improves the way people work together

- Rapid feedback loops - improve the chances of more motivated and better-performing team members